Overview

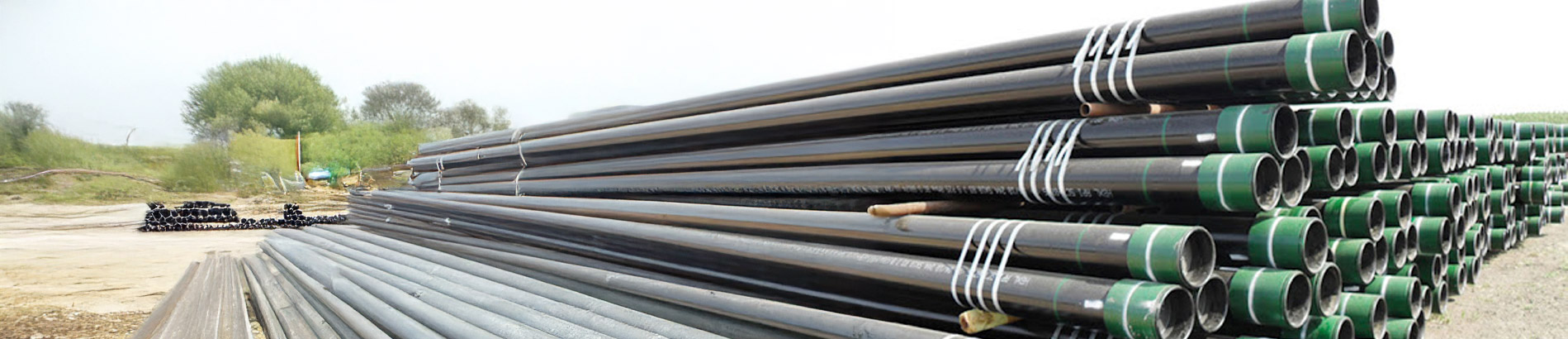

Seamless tube mills transform solid steel billets into finished OCTG through a sequence of heating, piercing, elongating, and sizing operations. These integrated facilities control quality from raw material to finished product.

Technical Specifications

QualityControlled from billet

CapacityVaries by mill

ProcessesPiercing, Mandrel mill, Plug mill, Pilger

Size RangeFacility dependent

Applications

Premium OCTG

Critical applications

Sour service grades

High-performance pipe

Frequently Asked Questions

What is Seamless Tube Mills?

Seamless tube mills transform solid steel billets into finished OCTG through a sequence of heating, piercing, elongating, and sizing operations. These integrated facilities control quality from raw material to finished product.

What are the applications of Seamless Tube Mills?

Seamless Tube Mills is commonly used for: Premium OCTG, Critical applications, Sour service grades, High-performance pipe.

What API standard applies to Seamless Tube Mills?

Seamless Tube Mills is manufactured according to API 5CT/5L specifications.

Manufacturers

No manufacturers linked yet.