Overview

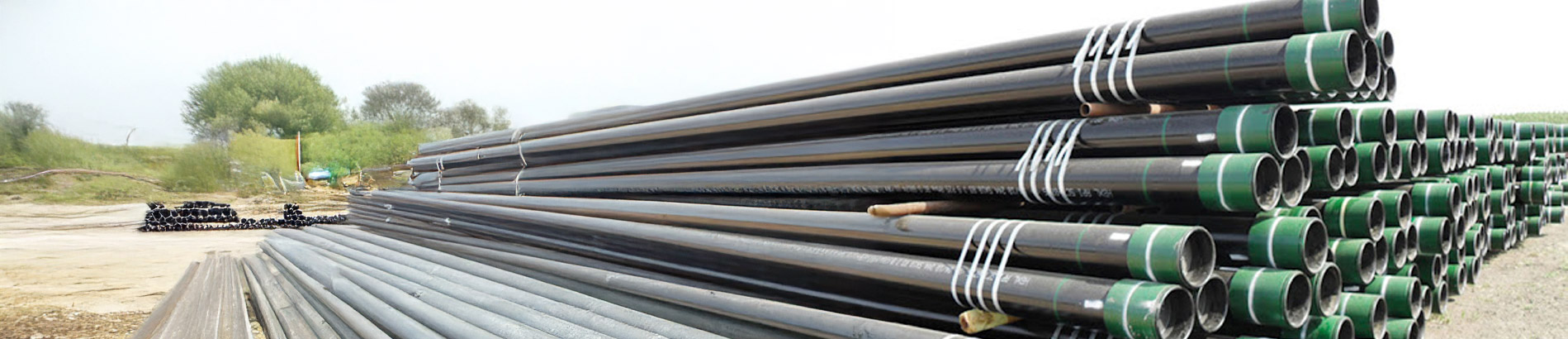

ERW mills produce welded pipe by forming flat steel strip and welding the longitudinal seam using high-frequency electric resistance. This economical process is suitable for many casing and line pipe applications.

Technical Specifications

WeldFull body normalized

ProcessContinuous ERW

AdvantagesHigh productivity, Consistent quality

Diameter Range2-3/8" to 16"

Applications

Casing production

Line pipe

Structural pipe

Cost-effective OCTG

Frequently Asked Questions

What is ERW Mills?

ERW mills produce welded pipe by forming flat steel strip and welding the longitudinal seam using high-frequency electric resistance. This economical process is suitable for many casing and line pipe applications.

What are the applications of ERW Mills?

ERW Mills is commonly used for: Casing production, Line pipe, Structural pipe, Cost-effective OCTG.

What API standard applies to ERW Mills?

ERW Mills is manufactured according to API 5CT/5L specifications.

Manufacturers

No manufacturers linked yet.